Portable Vacuum Loader Hire | 020 8571 3988

The reputation of IBS is renown across the UK for its commitment to quality products and services, delivering top engineering advice and assistance from professionals with decades of experience in the industry, as well as for ensuring value for money.

Being able to provide top quality services means understanding the products and services so that excellent customer care becomes an inevitable extension of that broad knowledgebase. Providing solutions and troubleshooting problematic issues can be executed with ease. Recommendations are based on thorough understanding of the service and the high level of expertise that IBS is proud to provide.

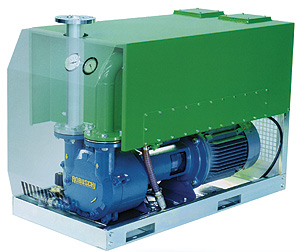

-large.jpg) Offering a variety of engineering services makes IBS a versatile one-stop-shop providing convenience to clients, as well as quality products. Services include processing engineering services, repairs, servicing and recondition of blowers, vacuums and pumps which can be done both on and off-site, site surveys and fault finding, metal spray painting and equipment hire of various shaft and blower sets, vacuum pumps and portable vacuum units.

Offering a variety of engineering services makes IBS a versatile one-stop-shop providing convenience to clients, as well as quality products. Services include processing engineering services, repairs, servicing and recondition of blowers, vacuums and pumps which can be done both on and off-site, site surveys and fault finding, metal spray painting and equipment hire of various shaft and blower sets, vacuum pumps and portable vacuum units.

In the event of down-time resulting from emergency breakdown, planned repairs and maintenance or upgrades, short-term demand for extra air, testing of new systems or accidental damage, IBS have fully packaged roots type Blower Sets ready and available to minimise production disruptions. All sets are supplied with electric motor drive and air ancillaries. In addition, pipework and fittings can also be supplied to suit customer’s connection points and accessibility. Where accessibly poses an issue, IBS can supply generator sets with fuel tanks and load cables.

Additional services, include Air Industrial Vacuuming Hire, Portable air conveying system Hire and Industrial Vacuum Loader hire, plus hire of a range of rotary vane, side channel and claw type machines for pressure applications with discharge pressures up to 2.0 bar gauge. Units and equipment are stored in locations across the UK for expediting delivery and reducing response time in case of unplanned downtime or emergencies. Units and sets can also be collected directly from IBS locations.

Customers who are planning for preventative maintenance or equipment upgrades have access to IBS process engineers who will come to site and based on their vast engineering knowledge and experience of almost any type of scenario, will assist with the planning, costing and implementation of equipment for any environment where blowers, vacuums and pumps are utilised. IBS can provide performance evaluations on electrical equipment, highlighting any potential energy cost savings resulting from the introduction of more efficient equipment, along with a full energy audit and a Total Cost of Ownership (TCO) evaluation so that customers have the opportunity to make a full cost evaluation of the solutions provided, including running costs. IBS is also able to service the majority of roots type blower makes and models, easily on site.

IBS believes in being proactively helpful which is why going the extra mile is major part of the culture of the company, an ethos which we believe is the reason why our customers keep coming back to us, buying the products that we provide and using our services, year after year. Our track record, combined with our reputation for excellence, is what enables IBS to continue to provide exceptional service.